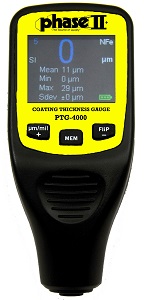

Description

The new PHASE II PTG-3525 can perform two different methods of calculating thickness measurement by utilizing the characteristics of both eddy current and magnetic induction.Testing performance is both non-destructive and extremely accurate.

With this state of the art thickness gage, you can easily detect the thickness of nonmagnetic coating on a magnetic substrate (ferrous) or an insulating coating on a non-magnetic conductive substrate (non-ferrous) utilizing our version that comes with 2-external probes.

The PHASE II PTG-3525 can be used in many areas of industry including manufacturing, general engineering, commercial inspection, etc. Main Technical Data

- Measuring range: 0-1000 u m max. or 0-40 mils

- Resolution: 0.1 u m / 0.01mils(0-99u m) or 1u m (over 100u m)

- Guaranteed tolerance: After one-point calibration: +/- 1-3%n or 2u m (whichever is greater)

- Display: 4 digits (digit height = 10mm/0.4”)

- Min. measuring area: 0.2” x 0.2” (5mm x 5mm)

- Min. radius of curvature: Convex: 0.12” (3mm) Concave: 1.2” (30mm)

- Min. substrate thickness: Ferrous: 20 mils (0.5um) Non-ferrous: 2 mils (50u m)

- Calibration: Zero Calibration Foil calibration

- Max. Surface temperature of test object: 302 degrees F (contact time max is 2 seconds)

- Power source: 4 AA batteries

- Dimensions: 161 x 69 x 32mm

- Weight: 9oz. (260g)

| Model No. | Description |

| PTG-3525 | Coating Thickness Gage w/ External Probes |