Description

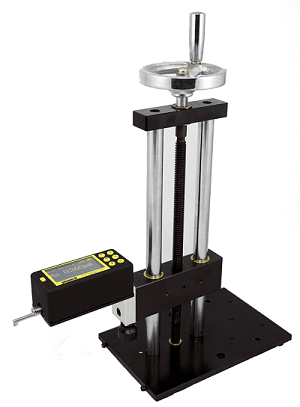

| Part No. SRG4000-050 Can be used with all Phase II 4000 series surface roughness testers/profilometers Range of travel: Approx. 4-13″ Height up to top bracket: 13″ Total height of stand: 18″ | |

| SRG4600-300 Small Hole Stylus For use on small holes under 2mm diameter and max depth of 4mm | |

| SRG4600-200 Deep Groove Stylus For use on deep grooves with min. width of 3mm and max depth of 10mm. Must use with support stand | |

| SRG4500-550 5″ Stylus Extension SRG4500-500 2″ Stylus Extension | |

| Part No. SRG4600-MP Mini Printer for 4600 only |

Surface Roughness Tester Profilometer Measurement Guide Surface roughness, for purposes of this forum, is the result of some machining process and its effect on the material surface in question.

Skid type surface roughness testers profilometers are common instruments used on the shop floor. A diamond stylus is traversed across the specimen and a piezoelectric pickup records all vertical movement. Peaks and valleys are recorded and converted into a known value of a given parameter.

Parameters differ in how they approach looking at peaks and valleys. The most popular parameter is “Ra”. Ra is commonly defined as the arithmetic average roughness. While the Ra parameter is easy and efficient, there are other parameters that can be more specific and useful depending on the application requirements. It is the parameters that enable us to define surface roughness.

Today, for the purpose of checking Ra values, the use of portable, hand held, surface roughness testers are not only economical, but are digital and easy to use. These surface roughness testers are a given necessity for any shop floor that receives work with Ra requirements.